Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

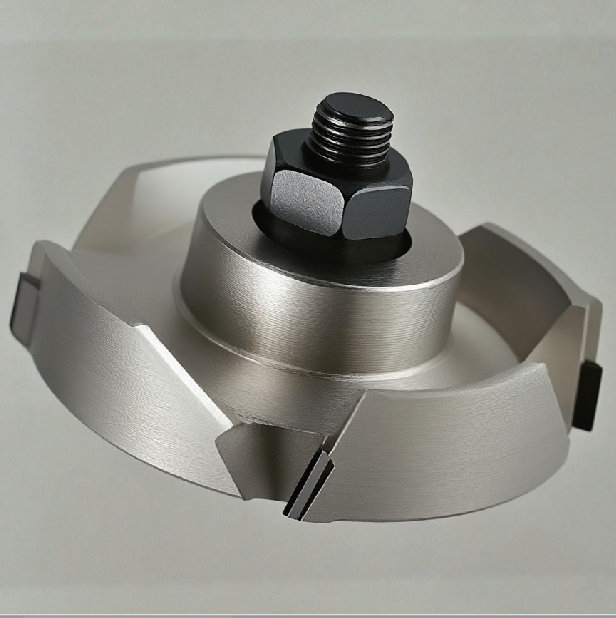

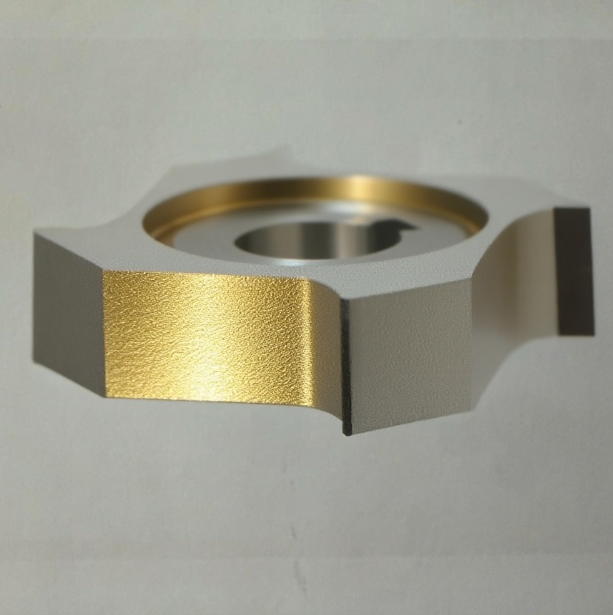

金刚石粗修刀 Diamond roughing tool

用于Homag和IMA封边机上,对实木,单板和塑料封边条的粗修和倒角。

Forflush cutting and chamfering of edge bandsOn Homag and lMA edgebanders

-

70*HSK25R*23*23*4

-

70*HSK25R*14*23*4

-

70*HSK25R*8*23*4

-

70*HSK25R*8*23*6

-

70*HSK25R*8*23*8

金刚石粗修刀,作为切削加工领域的关键工具,以其卓越的性能和广泛的应用,为各类加工工艺带来了更高的效率与精度。

一、核心材质

1. 刀头:采用高品质金刚石或PCD(聚晶金刚石)材料,硬度接近自然界最高水平,远超传统刀具材料,耐磨性是普通合金的数十倍,能在高速切削和恶劣工况下保持稳定的切削性能,有效减少刀具更换频率,提升加工效率。

2. 刀体:选用优质钢材或高强度铝合金材质。钢材刀体具备出色的强度和刚性,能承受较大切削力;铝合金刀体则以轻质、散热性好的优势,降低电机负载,提高加工稳定性,同时减轻操作人员劳动强度 。

二、产品特性

1. 强大切削力:独特的刀齿设计和锋利刃口,配合金刚石的高硬度,能轻松切入各种硬质材料,如木材、密度板、刨花板以及部分有色金属等,实现高效粗加工,快速去除大量材料,缩短加工周期。

2. 高精度加工:尽管是粗修刀,但通过精密制造工艺和严格质量把控,加工精度可达±0.1mm ,确保加工表面平整,为后续精修工序提供良好基础,减少废品率。

3. 长使用寿命:金刚石的高耐磨性,使刀具在长时间使用中磨损缓慢,正常工况下,使用寿命是普通合金粗修刀的5 - 10倍,降低刀具采购成本和维护成本。

4. 排屑顺畅:科学设计的排屑槽,能迅速将切削过程中产生的碎屑排出,避免碎屑堆积影响加工质量和刀具寿命,同时减少因排屑不畅导致的加工表面划伤、崩边等问题。

5. 稳定性高:经过动平衡处理,刀体在高速旋转时保持稳定,减少振动和噪音,保障加工过程平稳,提高加工精度和表面质量,延长设备使用寿命。

三、应用场景

1. 家具制造:用于板材开料后的边缘粗修,去除切割毛刺和不平整部分,为后续封边、砂光等工序做准备;在榫卯结构制作中,对榫头和榫眼进行初步切削加工,提高加工效率和精度。

2. 木地板生产:对木地板坯料进行粗加工,如铣削企口、修整板面,为精修工序提供精度保障,确保木地板拼接紧密、表面平整。

3. 门窗加工:对门窗框料进行粗修,去除多余材料,保证尺寸精度,为后续组装和表面处理奠定基础,适用于木质、塑钢、铝合金等多种材质门窗加工。

4. 木工工艺品制作:在大型木雕、木质摆件等工艺品制作初期,快速去除多余木料,勾勒出大致轮廓,提高创作效率 ,减少手工粗加工时间和劳动强度。

Introduction to the diamond rough repair knife product

Diamond rough repair knives, as a key tool in the field of cutting and processing, bring higher efficiency and accuracy to various processing technologies with their excellent performance and wide application.

1. Core material

1. Cutter head: It uses high-quality diamond or PCD (polycrystalline diamond) materials, with hardness close to the highest level in nature and far exceeding traditional tool materials. Its wear resistance is dozens of times that of ordinary alloys. It can maintain stable cutting performance under high-speed cutting and harsh working conditions, effectively reduce tool replacement frequency and improve processing efficiency.

2. Knife body: Choose high-quality steel or high-strength aluminum alloy material.The steel tool body has excellent strength and rigidity and can withstand large cutting forces; the aluminum alloy tool body has the advantages of lightweight and good heat dissipation, reducing the motor load, improving processing stability, and reducing the labor intensity of operators.

2. Product Features

1. Strong cutting force: The unique cutting teeth design and sharp edge, combined with the high hardness of diamond, can easily cut into various hard materials, such as wood, density board, particle board and some non-ferrous metals, to achieve efficient rough processing, quickly remove a large amount of materials, and shorten the processing cycle.

2. High-precision processing: Although it is a rough repair knife, the processing accuracy can reach ±0.1mm through precision manufacturing process and strict quality control, ensuring the smoothness of the processing surface, providing a good foundation for subsequent refining processes and reducing waste rate.

3. Long service life: The high wear resistance of diamond makes the tool wear slow during long-term use. Under normal working conditions, the service life is 5-10 times that of ordinary alloy rough repair knives, reducing tool procurement and maintenance costs.

4. Smooth chip removal: Scientifically designed chip removal grooves can quickly discharge debris generated during cutting, avoiding debris accumulation affecting processing quality and tool life, and at the same time reduces problems such as scratches and edge collapses in the processing surface caused by poor chip removal.

5. High stability: After dynamic balance treatment, the tool body remains stable when rotating at high speed, reducing vibration and noise, ensuring stable processing process, improving processing accuracy and surface quality, and extending the service life of the equipment.

III. Application scenarios

1. Furniture manufacturing: used for rough edge repair after the board is opened, remove cutting burrs and uneven parts, and prepare for subsequent edge sealing and sanding processes; in the production of mortise and tenon structures, the mortise and mortise are initially cut and processed to improve processing efficiency and accuracy.

2. Wood floor production: rough processing of wooden floor blanks, such as milling the entrance and trimming the board surface, provides accuracy guarantee for the renovation process, ensuring that the wooden floor is spliced tightly and the surface is flat.

3. Door and window processing: Coarse repair of door and window frame materials, remove excess materials, ensure dimensional accuracy, lay the foundation for subsequent assembly and surface treatment, and is suitable for door and window processing of various materials such as wood, plastic steel, aluminum alloy, etc.

4. Woodworking craft production: In the early stages of large-scale wood carvings, wooden ornaments and other handicraft production, quickly remove excess wood, outline rough outlines, improve creative efficiency, and reduce the time and labor intensity of handwork.